1. What is diesel generator efficiency?

The diesel generator efficiency refers to the ratio of useful electrical energy output to the total energy input from the diesel fuel. It is an important factor to consider when evaluating the performance and cost-effectiveness of a generator. Our METCL diesel generators are designed to convert fuel (diesel) into electrical energy with minimal waste.

2. How is diesel generator efficiency measured?

The diesel generator efficiency is typically measured by its fuel consumption and the electrical power output. The key parameter used to express this efficiency is Specific Fuel Consumption (SFC), which represents the amount of fuel required to generate a certain amount of electrical power. SFC is commonly expressed in units like grams per kilowatt-hour (g/kWh) or pounds per horsepower-hour (lb/hp-h).

The formula for calculating SFC is as follows:

Here’s a breakdown of the components:

- Fuel Consumption:

- This represents the amount of fuel consumed by the diesel generator during a specific period. It is usually measured in grams or pounds.

- Electrical Power Output:

- This is the amount of electrical power produced by the generator during the same period. It is typically measured in kilowatt-hours (kWh) or horsepower-hours (hp-h).

By measuring SFC, you can assess the diesel generator efficiency in converting fuel into electrical power. Lower SFC values indicate better fuel efficiency, meaning the generator can generate more electricity with less fuel consumption.

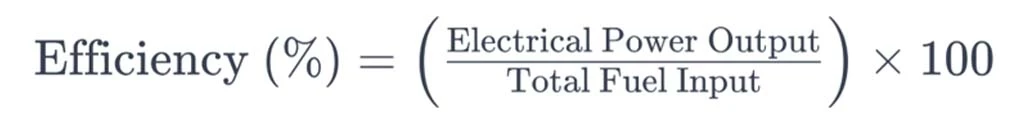

In addition to SFC, overall diesel generator efficiency is sometimes expressed as a percentage and is calculated using the following formula:

Here, the Total Fuel Input includes not only the fuel consumed by the engine to produce electricity but also any auxiliary power consumed by systems such as cooling, lubrication, and control systems. This diesel generator efficiency calculation provides a broader view of the generator’s overall performance.

It’s important to note that the diesel generator efficiency can vary based on factors such as load level, ambient conditions, and maintenance status. Generators are often most efficient when operating at or near their rated capacity.

3. What is the ideal load for maximum diesel generator efficiency?

The ideal load for maximum diesel generator efficiency is typically around 70-80% of its rated capacity. Diesel generators are designed to operate most efficiently within a certain range of loads, and this range is often referred to as the “design load” or “optimal load.”

Here are some key points related to the ideal load for maximum diesel generator efficiency:

- Rated Capacity:

- The rated capacity of a diesel generator is the maximum load it can handle continuously. Running a generator close to its rated capacity, ideally in the range of 70-80%, allows it to operate at its peak efficiency.

- Efficiency Curve:

- Diesel generators have an efficiency curve that shows how efficiently they convert fuel into electrical power at different load levels. The curve typically peaks in the 70-80% load range.

- Fuel Consumption and Heat Loss:

- At lower loads, the generator may experience higher specific fuel consumption (SFC) and increased heat losses, reducing overall efficiency. At very low loads, the generator may also experience issues such as “wet stacking,” where unburned fuel accumulates in the exhaust system.

- Maintenance Considerations:

- Operating a generator at or near its optimal load can also have positive effects on maintenance. It helps prevent issues associated with low-load operation, such as carbon buildup and incomplete combustion.

- Load Fluctuations:

- While operating at the optimal load is ideal for efficiency, generators are designed to handle varying loads. However, frequent and drastic load fluctuations can affect efficiency and contribute to wear and tear.

It’s important to note that the ideal load for maximum diesel generator efficiency may vary slightly depending on the specific design and characteristics of the diesel generator. Manufacturers often provide efficiency data and guidelines for optimal operation in the product documentation.

In practical applications, load requirements can vary, and it may not always be possible to maintain the ideal load. However, efforts should be made to operate the generator within a range that balances efficiency with the actual load demand. If the load is consistently too low, it’s advisable to consider load-banking or other measures to bring the generator closer to its optimal operating range.